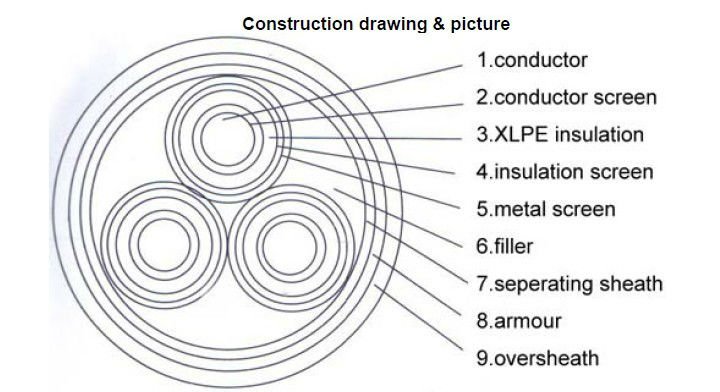

(1) conductor (or Conducting wire core):

Its function is conduction current. Have solid core and stranding core. Materials are copper, aluminum, silver, copper clad steel, aluminum, steel, etc., mainly used in copper and aluminum. The conductivity of copper is much better than aluminum.

2) refractory layer:

Only fire resistant cable has this structure. Its role is that in the fire the cable can withstand a certain period of time, to give people more time to escape.

3) insulation layer:

Coated on the outside of the conductor, the role is to isolate the conductor, to withstand the corresponding voltage, to prevent leakage of current.

Insulating materials have varied, some requirements of dielectric coefficient is smaller, to reduce the loss, have flame retardant properties and can resist high temperature, and some require cable in burning or not produce less smoke and harmful gas, some requirements are tolerant of oil, corrosion resistance, while others require soft.

4) shield layer:

Outside the insulation layer, the function is to limit the electric field and the electromagnetic interference.

For different types of cable, shielding materials are not the same, mainly has: copper wire braided, wrapping copper wire, aluminum wire, aluminum alloy wire) weaving, copper strip, aluminum foil, aluminum (steel) plastic belt, strip, etc. or longitudinally wrap lapping.

5) filling layer:

Filling's main role is to make the cable round, the structure is stable, some cable filler also plays the role of water resistance, fire resistance and so on. The main materials are polypropylene rope, glass fiber rope, asbestos rope, rubber and so on, a lot of kinds, but one major performance requirements are non absorbent material, of course, can not be conductive.

6) undersheath layer:

The role of the inner layer is to protect insulated wire core not damage by shield layer or armor layer.

The inner protection layer has extruded, wrapped and longitudinal forms. For high requirements, using extruded shape package form, low requirement uses wrapping or longitudinal form.

7) armored layer:

Armoured role is to protect the cable without damage. The most common is the steel tape armor and steel wire armour,

There are aluminium armour, stainless steel tape armoured etc. The main role to use steel tape armored layer is compression, steel wire armour role is mainly tensile. According to the size of the cable, armouring steel strip thickness is not the same, which are specified in the cable standard.

8) outer sheath:

The protective effect of the outer cable components.

There are three main types: plastic, rubber and metal. Which is the most commonly used plastic PVC plastic, polyethylene plastic, and according to the characteristics of cable, there are flame retardant, low smoke and low halogen, low smoke halogen-free type etc.

Leave a Reply